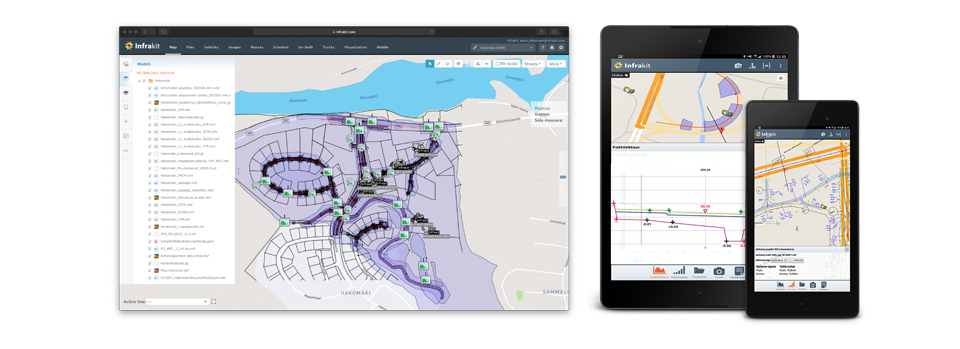

At the office or on the worksite Infrakit offers 24/7 access:

- Infrakit OFFICE™ to manage all information on a PC

- Infrakit FIELD™ to carry the project information on site with a mobile device

- Infrakit LINK™ to connect directly with surveying equipment and machine control systems

- Infrakit TRUCK™ to keep track of movements and activities of vehicles

Infrakit connects project participants into common information management system. Thanks to open formats and cloud technology, enhanced information flow enables collaboration for all stakeholders of civil construction project. Infrakit has intuitive visual approach to access all your information on map or on automated reports. This ensures that your whole team works for common targets and has up-to-date information easily in their hands – also when mobile.

Initial data & Bidding

On bidding-phase you can utilize drawings together with your location on Infrakit FIELD mobile app. Document your ground observations with built-in photo tools. Access PDFs and fill them up onsite for your safety reports, risk assessment, or anything you need to digitize. State of art situational awareness is reached by visualizing orthophotos and point clouds.

Design

On design phase Infrakit helps you in collaboration of multi-discipline design models. Powerful 3D visualization combines Building Information Modeling (BIM) and Geographic Information System (GIS) data seamlessly in web browser. Check constructability of models with built in model-checker and cross section tool. By using Infrakit, client of the project ensures they get the plan they procured!

Construction

The full power of Infrakit is unleashed at construction phase. Infrakit connects teams with mobile devices, surveying equipment and multi-vendor machine control fleets. Infrakit updates the as-planned models for field team and incorporates as-built data for real-time progress and quality monitoring. Machine usage data and truck haul monitoring, together with volume and schedule tracking, boosts efficiency of the jobsite to the max!

Project owners & Supervisors

Project owners benefit on Infrakit because projects are finished on time and in budget. The quality is improved due to automated progress monitoring that allows full digital transparency – all the way to the implement of the machine. Enhanced workflow, where construction work is carried out by 3D designs, reduces rework and waiting drastically and leads also to smaller CO2 emissions on project